Ceramic Coating vs Traditional Wax: Which Offers Better Protection?

Ceramic Coating vs Traditional Wax: Which Offers Better Protection?

Blog Article

Just How Ceramic Covering Protects Your Cars and truck's Paint and Keeps It Looking New

Ceramic finishing has actually emerged as an innovative remedy for automobile paint protection, using a powerful barrier against the elements. The result is a considerable reduction in paint deterioration and an enduring aesthetic allure.

What Is Ceramic Layer?

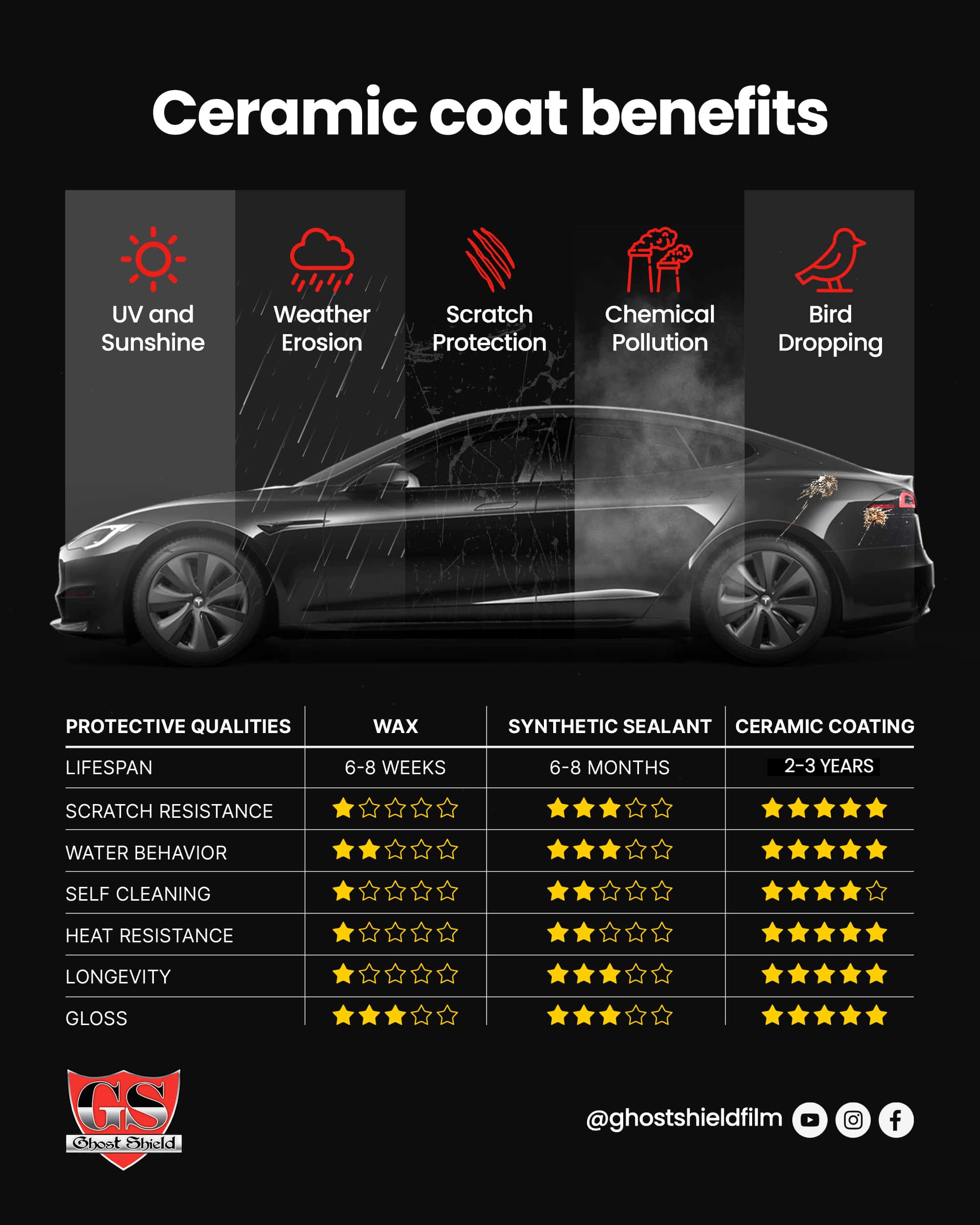

When applied appropriately, ceramic coverings develop a semi-permanent bond with the surface area of the lorry, using premium protection against UV rays, chemical discolorations, and minor scrapes - ceramic coating. Unlike conventional wax or sealants that might wear away within months, ceramic coverings can last for several years, depending on the product and maintenance

The application procedure involves thorough surface preparation, consisting of cleaning, decontaminating, and brightening the paint to ensure optimal bond. When the coating is applied, it treatments and hardens, resulting in a hydrophobic surface area that wards off water, grime, and dust. This hydrophobic building not just makes the vehicle easier to tidy but also boosts the total gloss and clearness of the paint, adding to a showroom-quality finish. As a result, ceramic layer is increasingly favored by cars and truck fanatics and professionals looking for resilient paint protection.

Benefits of Ceramic Finishing

Why should cars and truck owners consider purchasing ceramic finishing? The advantages of ceramic finishing extend much past mere aesthetic appeals, offering substantial defense and durability for a vehicle's paintwork. Among the main benefits is its extraordinary resistance to ecological impurities. Ceramic layers produce a hydrophobic surface area, permitting crud, dust, and water to slide off conveniently, decreasing the frequency of washing and the requirement for typical waxes.

Furthermore, ceramic coatings give a robust guard against UV rays, which can create paint to discolor and oxidize in time. This safety layer helps gloss and maintain the vibrancy of the car's shade, ensuring it looks new for several years. Ceramic coverings are understood for their longevity; they can last numerous years with proper maintenance, making them a cost-efficient financial investment in the long run (ceramic coating).

Another significant benefit is the ease of upkeep they provide. With a ceramic-coated surface area, minor scratches and swirl marks are much less most likely to take place, and when they do, they are easier to buff out. In general, the financial investment in ceramic finishing not only enhances the aesthetic charm of a lorry but also offers long lasting security that can save cars and truck proprietors money and time.

Just How Ceramic Finish Functions

Understanding how ceramic covering works is important for automobile owners considering this protective service for their car's paint. Ceramic finishings are composed of sophisticated nanotechnology that forms a long lasting, safety layer over the surface of the automobile's paint. When applied, these liquid polymers bond chemically with the manufacturing facility paint, developing a strong, hydrophobic layer that wards off water, dirt, and other contaminants.

The primary component in ceramic coverings is silicon dioxide (SiO2), which provides the covering's firmness and resistance to UV rays, chemicals, and scratches. This molecular bonding produces a protective shield that is considerably tougher than typical wax or sealers, providing long-lasting defense. The hydrophobic nature of the finish indicates that water beads up and rolls off the surface area, taking dust and grime with it, therefore making the automobile simpler to clean.

Application Refine of Ceramic Finish

The application process of ceramic coating needs cautious preparation and attention to information to make sure ideal results. At first, the vehicle needs to undergo a thorough cleansing to remove dust, crud, and pollutants. This step often consists of a clay bar treatment to remove embedded fragments that might compromise the layer's bond.

Following the cleansing, a comprehensive examination of the paint surface is essential. Any type of existing blemishes, such as scratches or swirl marks, need to be resolved with sprucing up. This ensures a smooth and reflective surface, improving the last look of the ceramic covering.

As soon as the paint is prepared, the ceramic covering is applied in a controlled atmosphere to stop dirt and debris from contaminating the surface. Using a specialized applicator, the finishing is uniformly dispersed in areas, enabling appropriate bonding with the paint. It is critical to adhere to the supplier's standards regarding curing times and ecological problems during application.

After the application, a curing period is required for the finishing to accomplish its complete protective properties. This process can vary in duration based upon the details product used, however it is crucial for attaining the preferred resilience and long life of the ceramic finishing.

Upkeep Tips for Ceramic Finish

Maintaining a ceramic covering is necessary for maintaining its safety Read Full Report homes and making certain the long life of your automobile's outside. Stay clear of automatic automobile cleans, as their rough chemicals and brushes can degrade the coating.

After washing, rinse thoroughly and dry the car with a tidy microfiber towel to avoid visit our website water places. It's suggested to carry out upkeep cleans every two weeks to keep the coating in great problem.

Additionally, think about using a devoted ceramic finish booster or spray sealer every few months. These products boost the hydrophobic residential or commercial properties and add an added layer of protection.

Examine your automobile routinely for any type of impurities such as tree sap, bird droppings, or roadway tar, and remove them immediately making use of a clay bar if required. Park your auto in a garage or use a cars and truck cover to decrease exposure to severe ecological components. ceramic coating. By following these upkeep suggestions, you can make sure that your ceramic covering remains reliable and your cars and truck keeps its display room sparkle

Conclusion

To conclude, ceramic coating acts as a necessary protective measure for automotive paint, supplying many benefits such as enhanced longevity and resistance to ecological risks. The advanced chemical bonding procedure guarantees have a peek at these guys a lasting shield versus pollutants, UV rays, and oxidation, thus preserving the lorry's visual charm. Proper application and maintenance are important for making the most of the performance of ceramic finishings, ultimately adding to a car's long life and preserving a showroom-quality coating over time.

Ceramic layer is an innovative protective remedy designed to protect the appearance and enhance of car paint. Ceramic finishing is increasingly favored by cars and truck lovers and experts seeking long-lasting paint protection.

Recognizing exactly how ceramic layer works is important for car owners considering this safety solution for their car's paint. Ceramic layers are composed of sophisticated nanotechnology that develops a sturdy, protective layer over the surface of the automobile's paint.The key component in ceramic finishes is silicon dioxide (SiO2), which provides the finish's hardness and resistance to UV rays, scrapes, and chemicals.

Report this page